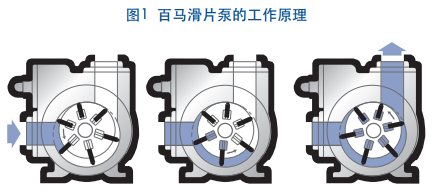

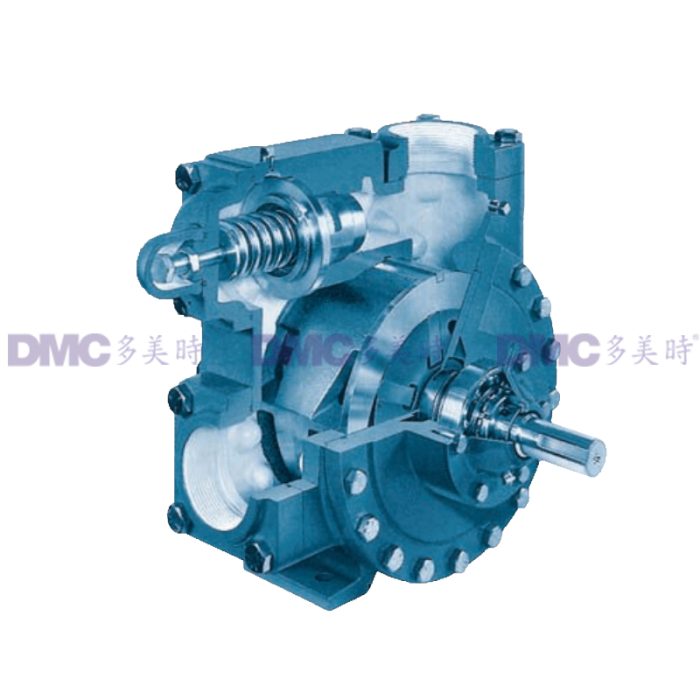

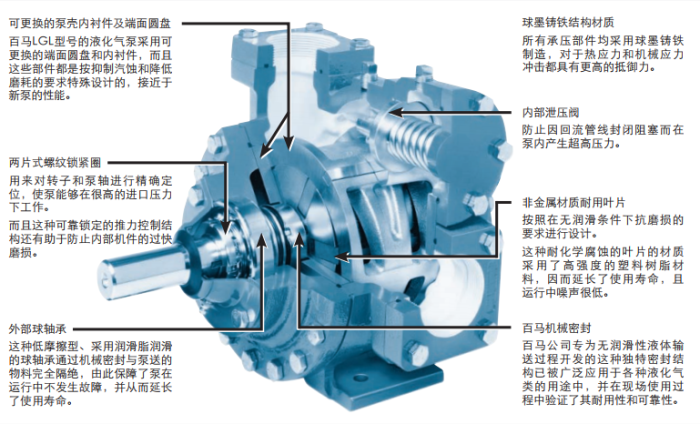

America Blackmer LGLD Series Oil Sliding Vane Pumps

Brand: Blackmer

Size: LGLD Series

Connection: Flange

Applications: LPG, Oil depot, irrigation area, tank truck system, etc

Overview of Blackmer GLD Series Oil Sliding Vane Pumps:

This high strength pump type is ideal for use in oil depots, multi-station cylinder filling, vaporizers, tank trailers and transportation vehicles.

This type of pump is available in single-ended or two-ended drive shafts with 2 “,3 “and 4″ orifice gauges, with capacity ranging from 30 to 350 U.S. gallons per minute (114-1,325 liters per minute). LGLD2 and LGLD3 pump models have been widely used in tank trailers for a long time because of the dual-end driven pump shaft design, which can easily adjust the position of the pump to realize clockwise or counterclockwise rotation of the pump shaft.

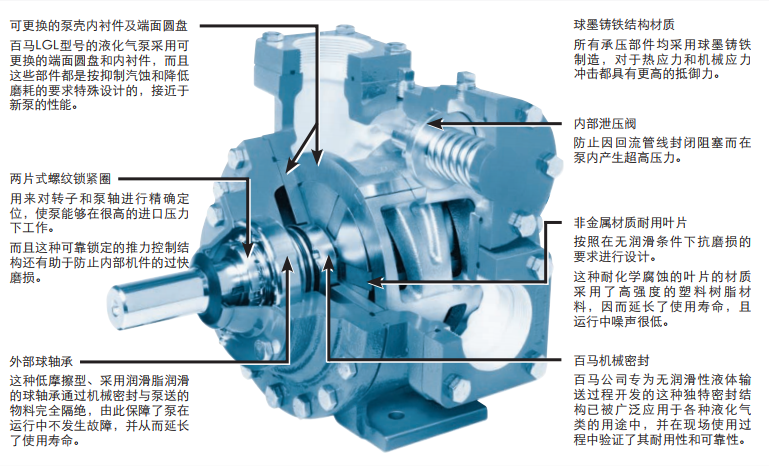

All models are equipped with a built-in safety valve and replaceable pump shell lining and end disks to facilitate reloading of the pump chamber if necessary. In addition, this type of pump set on the cavitation inhibition lining can play a role in reducing noise, vibration and wear.

Standard structural materials used include buna-n (nitrile rubber) mechanical seals and Duravanes high durability blades for conveying LPG and anhydrous ammonia for longer service life. Differential pressure of up to 150 LBS/in² (10.34 bar) for 2″ and 3″ pumps and 125 LBS/in² (8.62 bar) for 4” pumps. The inlet and outlet of the pump shall be in the form of NPT threaded mating flange or welded flange.

The driving device of the oil sliding vane pump mounted on the vehicle

The Blackmer LGLD2 pump is usually installed on the bottom plate of the tank trailer or on the steel backing plate directly welded on the tank. The 3″ and 4″ pump types can be mounted in a number of different ways, usually near or between the landing gear.Pumps mounted on vehicles are usually driven by a P.T.O. or hydraulic drive system. Pump systems for various types of tank trailers and transport vehicles.

Blackmer LGLD series oil sliding vane pump selection data

The pump performance curve shown on this page can be used to select the appropriate pump type for the tank car or transportation vehicle system. The data table shown on the right can be directly used for the standard pump or unit. The limit of shaft power for the unit drive and base of the pump set is listed in the table. Check the limits listed in the table against the pump shaft power requirements listed in the performance curve. For continuous load use, 400 RPM or lower pump speeds are generally recommended.