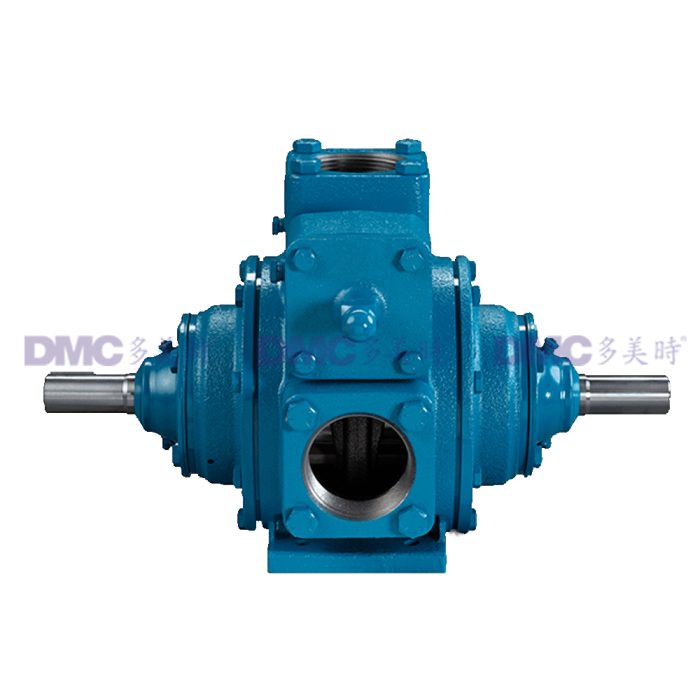

Blackmer TXD Series TXD3E Cast Iron Sliding Vane Pump: High-Efficiency Solution for Biofuel Transfer

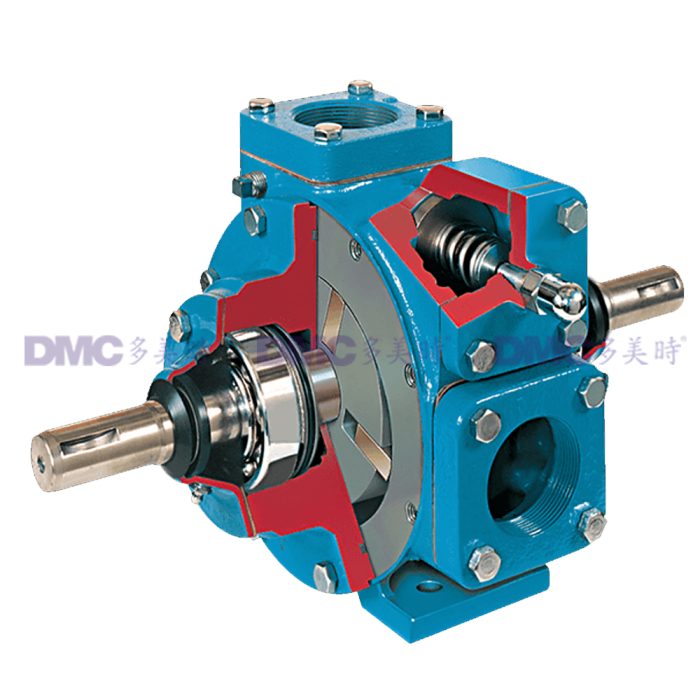

How Blackmer’s Sliding Vane Action Works

Reliability

Durable pumps for fast and quiet operation. Sliding vane design provides sustained performance and trouble-free operation.

Unique Features

- Adjustable relief valve protects pump from excessive pressure.

- Optional air-operated relief valve offers easy hose and nozzle handling.

- T-type strainers are available to protect pumping systems from damage caused by welding slag and foreign matter in piping and tanks.

Sizing Options

Available in 1.5, 2, 2.5, 3, and 4-inch port sizes with flow rates from 10 to 500 U.S. gpm (2 to 113 m³/h) and pressures up to 125 psi (8.6 bar).

Applications

- Fuel oil delivery

- Transport of:

– Petrochemicals

– Gasoline

– Biofuels

– Solvents

– Lubricating oil

– And many more - Fleet refueling

- Aviation refuelers

TXD Series Specific Features

TXD models are equipped with FKM O-rings and Blackmer mechanical seals compatible with all biodiesel and ethanol blends. TXD options include corrosion-resistant relief valve, pneumatic relief valves, and Buna or PTFE elastomers and seals.

Performance Data

Maximum Operating Limits

| Pump Model | Rated Pump Speed (rpm) | Flow Rate (gpm) | Flow Rate (L/min) | Flow Rate (m³/h) | Power (hp) | Power (kW) |

|---|---|---|---|---|---|---|

| TX1.5 | 780 | 52 | 197 | 12 | 2.4 | 1.8 |

| TXD2 | 600 | 40 | 151 | 9 | 1.9 | 1.4 |

| TXD2.5 | 400 | 25 | 95 | 6 | 1.3 | 1.0 |

| TXD3 | 640 | 120 | 454 | 27 | 5.0 | 3.7 |

| TXD4 | 520 | 98 | 371 | 22 | 3.8 | 2.8 |

| TX4 | 640 | 263 | 995 | 60 | 11.1 | 8.3 |

| TX4 | 520 | 211 | 799 | 48 | 8.6 | 6.4 |

| TX4 | 500 | 505 | 1,911 | 115 | 18.2 | 13.6 |

| TX4 | 400 | 405 | 1,533 | 92 | 15.0 | 11.2 |

Note: Appropriate capacities and horsepower (hp) are based on 100 ssu (22 cP) fluid at 50 psi (3.4 bar) delivered pressure. Refer to Characteristic Curves for flow rates and torque requirements at other pressures and viscosities.

Nominal Pump Performance

| Pump Model | Flow Rate (gpm) | Flow Rate (L/min) | Speed (rpm) | Viscosity (ssu / cP) | Differential Pressure (psi / bar) | Working Pressure (psi / bar) | Temperature (°F / °C) |

|---|---|---|---|---|---|---|---|

| TX1.5 | 56 | 212 | 780 | 20,000 / 4,250 | 125 / 8.6 | 175 / 12.1 | 300 / 149 |

| TXD2 | 87 | 329 | 780 | 20,000 / 4,250 | 125 / 8.6 | 175 / 12.1 | 300 / 149 |

| TXD2.5 | 157 | 594 | 780 | 20,000 / 4,250 | 125 / 8.6 | 175 / 12.1 | 300 / 149 |

| TXD3 | 270 | 1,022 | 640 | 20,000 / 4,250 | 125 / 8.6 | 175 / 12.1 | 300 / 149 |

| TX4 | 505 | 1,911 | 500 | 20,000 / 4,250 | 125 / 8.6 | 175 / 12.1 | 240 / 116 |

Dimensions

Pump Rotation

Blackmer TXD models are equipped with a double-ended drive shaft for either clockwise (RH) or counterclockwise (LH) rotation. Standard rotation for the TX1.5 is counterclockwise (LH) when viewed from the drive shaft. Standard rotation for the TX4 model is clockwise (RH).

Options

- Buna or PTFE O-rings

- Pneumatic relief valve

- Hydraulic Motor Adapters

- Strainers

Dimensional Data (in inches and millimeters)

| Model | A | B | D | E | G | K | M | Q | S | T | AA | BB | DD | TT | Approx. Weight |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| TX1.5 | 1¹/8" | ¹/4" | 713/16" | 51/16" | 31/8" | 61/2" | 4" | 81/2" | 7" | 39/16" | – | – | 103/8" | – | 61 lbs / 28 kg |

| TXD2 | 1¹/8" | ¹/4" | 8" | 51/4" | 31/2" | 61/2" | 4" | 811/16" | 61/8" | 37/8" | 83/4" | 85/16" | 107/8" | 109/16" | 121/8" 70 lbs / 32 kg |

| TXD2.5 | 1¹/8" | ¹/4" | 83/4" | 6" | 47/8" | 7" | 4" | 95/8" | 613/16" | 315/16" | 91/2" | 811/16" | 115/8" | 115/16" | 135/16" 94 lbs / 43 kg |

| TXD3 | 1¹/8" | ¹/4" | 95/8" | 67/16" | 43/8" | 71/4" | 53/8" | 1213/16" | 89/16" | 415/16" | 1011/16" | 97/16" | 123/8" | 153/8" | 152 lbs / 69 kg |

| TX4 | 1¹/2" | ³/8" | 11" | 81/4" | 7" | 91/2" | 63/8" | 151/2" | 81/2" | 63/8" | – | – | – | – | 295 lbs / 134 kg |

| Brand |

Blackmer |

|---|